Grating clamps play a crucial role in securing industrial grating systems. They ensure stability, improve safety, and simplify installation in demanding industrial environments. Explore their applications, benefits, and importance in detail.

How Grating Clamps Ensure Safety and Stability in Industrial Grating Systems

In industrial environments, safety and stability aren’t just buzzwords—they are non-negotiable requirements. Imagine a factory floor, offshore oil rig, or power plant walkway without secure flooring. One loose or displaced grating panel could lead to devastating accidents, downtime, and even lawsuits. This is where grating clamps step in as silent guardians, ensuring industrial grating systems remain steadfast and secure.

Grating clamps may seem small, but their role in preventing accidents and maintaining structural stability is monumental.

What Are Grating Clamps?

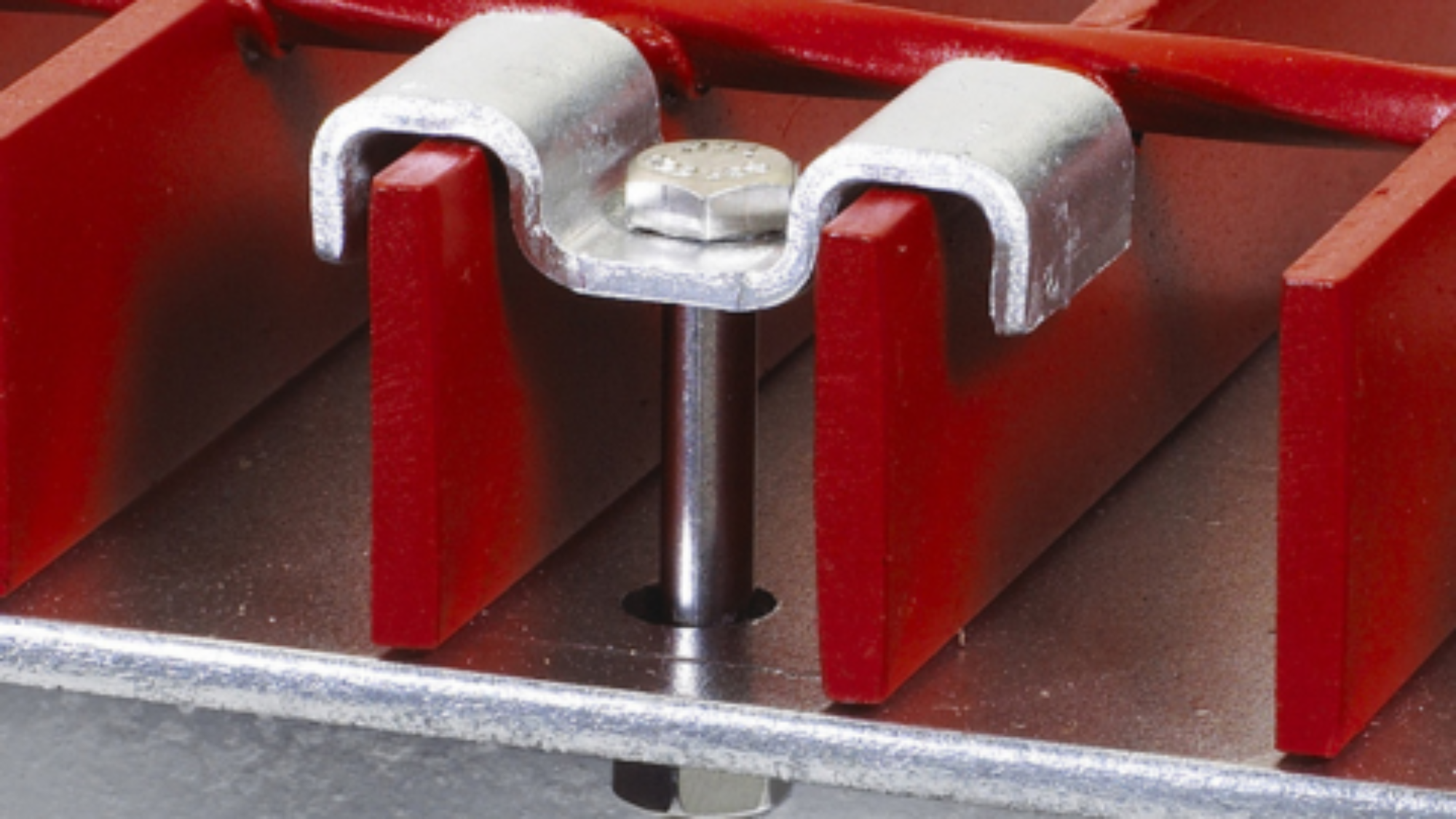

Grating clamps are fastening devices designed to secure industrial grating panels to underlying support structures. These panels, often made of steel grating or other durable materials, are used in various industrial settings as flooring, walkways, or platforms. Without proper fastening, these panels can shift, causing safety hazards and operational inefficiencies.

Grating clamps are usually made of tough, corrosion-resistant materials like galvanized steel or stainless steel, making them capable of withstanding the harsh environments and high stress typical of industrial applications. But their true magic lies in their ability to lock grating panels in place without the need for permanent fixtures like welding or drilling.

This flexibility makes them indispensable for industries that demand both safety and efficiency.

Why Are Grating Clamps So Important?

It’s easy to overlook something as small as a grating clamp, but their impact is anything but negligible. Here’s why they’re essential:

- Ensures Safety and Prevents Accidents

One of the biggest risks in industrial settings is a loose or displaced grating panel. Workers walking on unstable grating could trip, fall, or worse, get seriously injured. By securely fastening the grating panels in place, clamps reduce the risk of such incidents, making them vital to workplace safety.

- Supports Heavy Loads

Industrial floors are often subjected to heavy machinery, equipment, and foot traffic. Grating clamps provide the necessary stability to handle these loads, ensuring the grating doesn’t buckle or move under pressure.

- Simplifies Installation and Maintenance

Unlike welding or drilling, which can be time-consuming and labor-intensive, grating clamps are easy to install and adjust. They’re perfect for facilities that frequently reconfigure their layouts or need temporary flooring solutions.

- Prevents Structural Damage

Welding and drilling can weaken the grating panels or their supporting structures over time. Grating clamps, on the other hand, hold the panels securely without compromising their structural integrity.

- Complies with Industrial Standards

Many industries have strict safety standards and regulations, particularly when it comes to flooring. Grating clamps help businesses meet these requirements, ensuring compliance with workplace safety laws.

Types of Grating Clamps: Choosing the Right One

Not all grating clamps are created equal. Different environments and applications call for different types of clamps. Here are the most common ones:

- Saddle Clips

These are the go-to solutions for most grating installations. Saddle clips sit on top of the grating bar and are bolted down to the support structure. They’re easy to install and provide excellent stability.

- G-Clamps

For areas with limited access or where top-down installation isn’t possible, G-clamps are the ideal choice. They secure the grating from underneath, offering a tight grip even in challenging conditions.

- C-Clamps

C-clamps are versatile and great for temporary setups. They’re easy to attach and remove, making them ideal for applications where grating panels need frequent adjustments.

- Weld-Lok Clamps

When heavy-duty applications demand extra strength, Weld-Lok clamps combine the flexibility of clamping with the durability of welding. They’re often used in high-load or high-vibration environments.

How to Install Grating Clamps: A Step-By-Step Guide

Installing grating clamps is relatively simple, but attention to detail is key to ensuring a secure fit. Here’s a quick guide:

- Prepare the Area

- Inspect the support structure and grating panel for any debris, rust, or damage.

- Clean the surfaces to ensure a smooth installation.

- Select the Right Clamp

- Choose a clamp that’s compatible with your grating panel’s material, size, and load requirements.

- Align the Grating

- Position the grating panel over the support beams, making sure it’s aligned correctly.

- Attach the Clamps

- Place the clamp over the grating bar and secure it using bolts or screws. Tighten the fasteners enough to hold the grating securely, but don’t overtighten, as this could damage the grating or clamp.

- Test for Stability

- Walk over the grating to test for any movement or instability. If the panel shifts, adjust the clamps until it’s firmly in place.

Benefits of Grating Clamps in Industrial Applications

Why choose grating clamps over other fastening methods like welding or drilling? The benefits speak for themselves:

- Safety: Keeps workers safe by preventing accidents caused by loose grating.

- Durability: Protects the structural integrity of both the grating and the support beams.

- Cost-Efficiency: Reduces long-term maintenance costs.

- Flexibility: Allows for easy adjustments and reconfiguration.

- Time-Saving: Simplifies installation and eliminates the need for complex tools.

Industries That Rely on Grating Clamps

Grating clamps are used in a variety of industries, each with unique safety and stability needs:

- Oil and Gas

Offshore rigs and refineries demand robust grating systems for walkways and platforms. Grating clamps ensure these systems remain secure, even in harsh conditions.

- Manufacturing

Factory floors require durable, anti-slip grating to handle heavy machinery and foot traffic. Clamps provide the stability needed to keep operations running smoothly.

- Power Plants

Cooling towers, maintenance platforms, and other power plant structures depend on grating clamps for secure, long-lasting installations.

- Water Treatment Facilities

Grating clamps are essential in wastewater treatment plants, where grating covers drainage systems and tanks.

The Unsung Heroes of Industrial Safety

Grating clamps may not make headlines, but their role in industrial safety and stability is nothing short of heroic. From securing steel grating to simplifying installation, these small devices punch well above their weight.

Whether you are installing industrial flooring on an offshore oil rig, a manufacturing plant, or a power station, grating clamps ensure your grating systems are up to the task. They provide the stability, safety, and durability needed to keep industrial operations running smoothly—and workers protected.

So, the next time you see a sturdy industrial floor, remember: it’s the humble grating clamp that’s holding it all together.For reliable grating clamps and industrial flooring solutions, trust Greatweld Engineering Pvt. Ltd. Visit our website https://greatweld.com/, or call us at +91 8956049361, or visit Gat No. 213, 214/1, Markal Udyog Nagar, Pune – 412105, Maharashtra, India, for expert solutions tailored to your needs.