Steel Grating vs Aluminium Grating: Which Material Should You Choose?

When it comes to metal grating, steel, and aluminium are two of the most popular options on the market. But which one is right for you? From industrial platforms to decorative walkways, your choice of grating material can make or break the success of your project.

Steel and aluminium grating differ significantly in terms of weight, strength, corrosion resistance, and cost. In this article, we will break down their pros and cons, helping you decide which material fits your needs best.

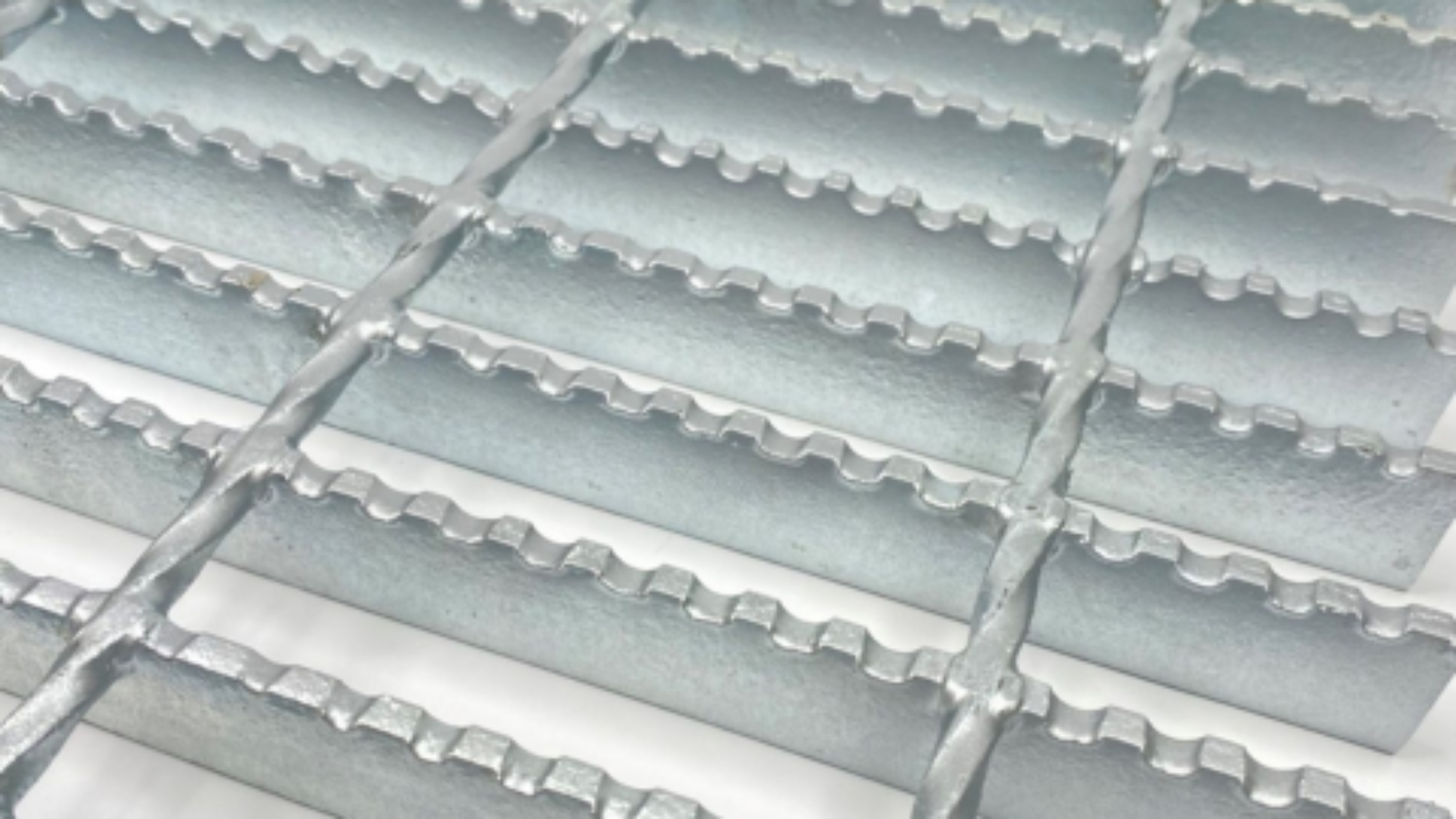

Understanding Steel Grating: The Heavy-Duty Workhorse

Steel grating is a robust, reliable material often used in heavy-duty applications. Made from either carbon steel or stainless steel, it’s known for its incredible strength and durability.

Why Choose Steel Grating?

- Exceptional Strength: Steel grating is engineered to handle heavy loads, making it perfect for industrial floors, platforms, and drainage systems. It’s the go-to option for projects requiring serious load-bearing capacity.

- Cost-Effective: Compared to aluminium, steel grating is generally more affordable upfront, which is ideal for budget-conscious projects.

- Versatile Applications: Steel mesh panels can be customized in various patterns and sizes to fit industrial, commercial, or even architectural uses.

Limitations of Steel Grating

While steel grating has its advantages, it’s not without its downsides. Steel is heavy, which can complicate installation and transportation. It’s also susceptible to corrosion unless treated with protective coatings like galvanization or painted finishes. Regular maintenance is essential to keep steel grating in top shape, especially in outdoor or humid environments.

Best Applications for Steel Grating

- Industrial floors and platforms that require high load capacity.

- Stair treads and walkways in factories and warehouses.

- Heavy-duty drainage systems or trench covers.

Understanding Aluminium Grating: The Lightweight Contender

If steel is the workhorse of grating materials, aluminium is the nimble and corrosion-resistant alternative. Aluminium grating offers a lightweight solution for projects where reducing weight is crucial.

Why Choose Aluminium Grating?

- Lightweight and Easy to Handle:Aluminium grating is significantly lighter than steel, which makes it easier to transport, install, and work with. This can save time and labor costs, especially in projects requiring mobility.

- Corrosion Resistance:Aluminium is naturally resistant to rust and oxidation, making it ideal for wet or chemical-heavy environments like marine platforms or food processing facilities.

- Sleek Aesthetic Appeal:Aluminium grating has a clean, modern look that works well in decorative applications.

Limitations of Aluminium Grating

Aluminium’s lightweight nature is also its Achilles’ heel when it comes to strength. It can’t handle the same heavy loads as steel grating, making it unsuitable for high-traffic or heavy-duty applications. Additionally, aluminium tends to have a higher upfront cost compared to steel.

Best Applications for Aluminium Grating

- Marine platforms and offshore oil rigs where corrosion resistance is key.

- Lightweight walkways, bridges, and ramps.

- Food processing facilities require hygienic and rust-free materials.

Key Factors to Consider: Steel vs Aluminium Grating

To choose the right material, consider the following factors based on your project requirements:

- Strength and Durability

Steel grating wins hands down when it comes to load-bearing capacity. If your project involves heavy equipment, industrial platforms, or high-traffic areas, steel is your best bet. Aluminium, while durable for its weight, is better suited for light-to-medium-duty applications.

- Weight

Aluminium grating is lightweight, making it easier to transport and install. This makes it ideal for applications where portability or weight reduction is a priority. Steel grating, being heavier, offers greater stability but may require more effort to handle.

- Corrosion Resistance

If your project is in a wet or humid environment, aluminium grating is naturally resistant to rust and oxidation. Steel grating, on the other hand, needs protective coatings like galvanization to prevent rust, adding to its maintenance needs.

- Cost

Steel grating is generally more affordable upfront, which is why it’s so popular for industrial use. Aluminium grating, while pricier, often pays off in the long run due to its low maintenance and longer lifespan in corrosive environments.

- Aesthetic Considerations

If aesthetics play a role in your project, aluminium grating offers a sleek, polished finish that complements modern designs. Steel grating can also look great but typically requires extra finishing to achieve a similar aesthetic.

Environmental Impact: Is Aluminium the Greener Option?

Both steel and aluminium are recyclable, making them eco-friendly choices. However, aluminium has an edge when it comes to sustainability. Its recycling process consumes less energy and reduces its carbon footprint compared to steel. If environmental impact is a priority, aluminium grating is the greener option.

Which One Should You Choose?

Still unsure which material to pick? Here’s a quick rundown:

- Choose steel grating if your project demands high strength, heavy load capacity, and a lower upfront cost. It’s the go-to option for industrial platforms, stair treads, and drainage systems.

- Opt for aluminium grating if you need lightweight, corrosion-resistant material for marine environments, decorative designs, or portable walkways.

By aligning your choice with your project’s unique needs—whether it’s weight, durability, or environmental resistance—you’ll ensure long-term success.

Steel and Aluminium Grating in Action: Real-World Examples

- Industrial Floors: Steel grating is used in factories to support heavy machinery and high foot traffic.

- Marine Walkways:Aluminium grating provides corrosion resistance and lightweight durability for offshore oil rigs.

- Architectural Projects:Aluminium grating adds a modern, polished look to decorative installations, while steel grating offers a rugged aesthetic in industrial designs.

Wrapping It All Up

Choosing between steel grating and aluminium grating is all about understanding your project’s priorities. Steel grating excels in strength and cost-efficiency, while aluminium grating is unbeatable for lightweight and corrosion-resistant applications.

Evaluate your project’s requirements, including load capacity, environmental exposure, and aesthetic needs, to make an informed choice. Whether you go with steel or aluminium, both materials bring unique benefits to the table.

Ready to get started? Contact Greatweld Engineering for high-quality steel and aluminium grating solutions tailored to your industrial, commercial, or architectural needs. With a proven track record of reliability and customization, they specialize in durable, corrosion-resistant, and heavy-duty grating options. Visit them at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India, call +91 8956049361, or explore their website at www.greatweld.com. Reach out today and let their expertise ensure the success of your project!