Grating clamps might seem like minor components, but they play a massive role in improving the strength, stability, and durability of structures. Whether you are securing steel grating for industrial or architectural purposes, these clamps provide reliable support and simplify installation.

Grating Clamps and Their Role in Enhancing Structural Integrity

When it comes to building durable and robust structures, every component plays a part. Grating clamps are among the unsung heroes in structural engineering, providing a seamless solution for securing grating installations. Designed for use in industrial plants, walkways, bridges, and other steel structures, these clamps ensure that the grating remains stable and resistant to heavy loads or vibrations.

What Are Grating Clamps?

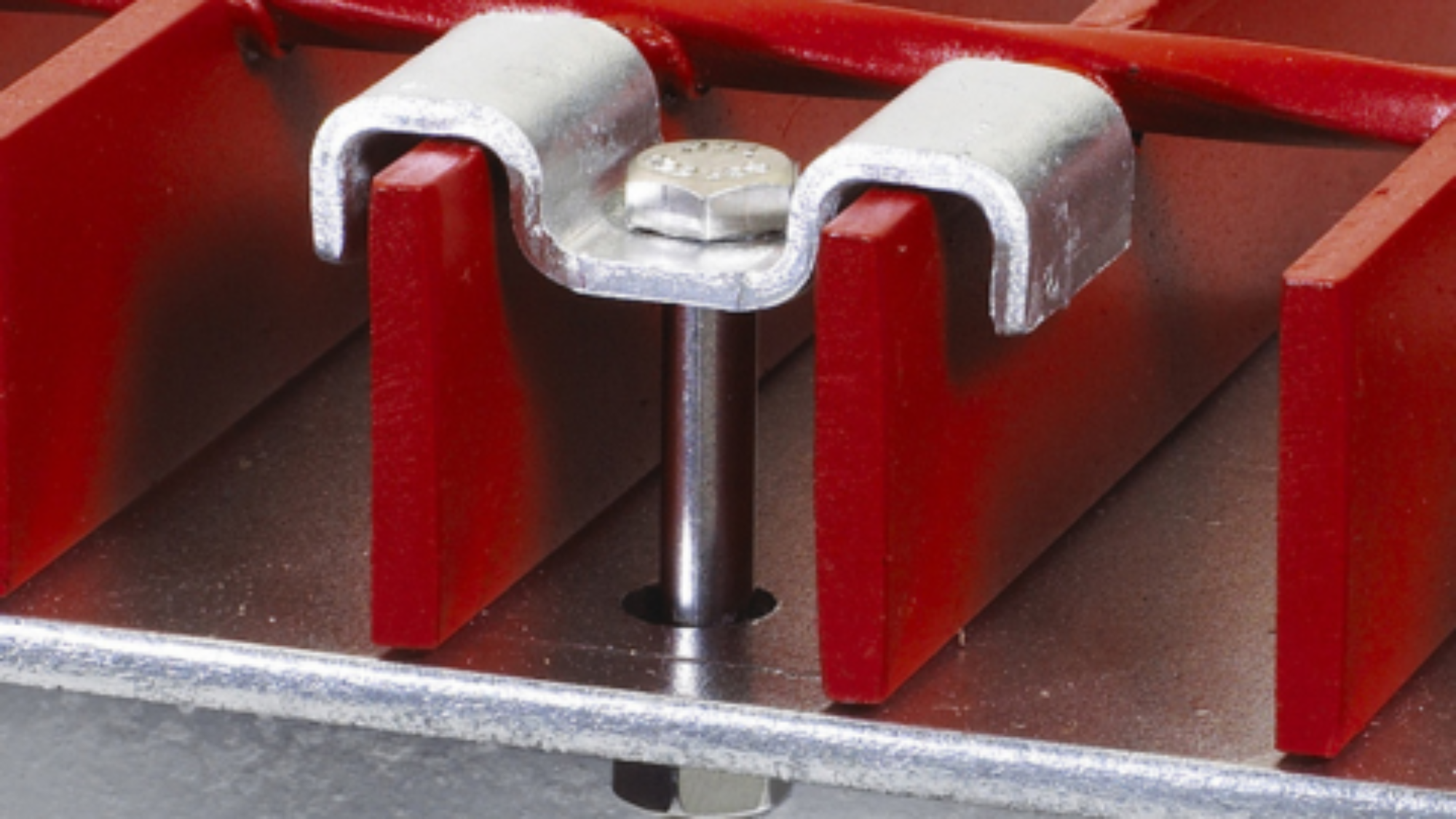

Grating clamps are hardware components designed to secure steel gratings onto structural frameworks without the need for welding or drilling. They serve as a fastening system, holding the grating firmly in place while allowing for quick and easy adjustments.

These clamps are typically made of steel, galvanized steel, or other durable materials that can withstand harsh conditions, heavy loads, and corrosion. Their primary function is to enhance the safety and performance of grating installations, ensuring that they don’t shift, loosen, or fail under pressure.

The Function of Steel Grating Clamps

Grating clamps play a crucial role in various applications. Their functionality includes:

- Securing Gratings Firmly in Place

By providing a strong grip, grating clamps eliminate the risk of gratings moving or dislodging during use. This is especially vital in areas prone to high traffic, vibrations, or heavy equipment loads.

- Allowing for Easy Installation and Removal

Unlike traditional methods like welding, grating clamps make it simple to install or remove gratings for maintenance or replacement. This saves time and reduces labor costs.

- Minimizing Structural Damage

Since grating clamps don’t require drilling or welding, they help maintain the structural integrity of the framework. This is particularly important when working with coated or corrosion-resistant materials.

- Adapting to Various Applications

Grating clamps come in different designs and sizes to accommodate diverse grating types, including bar grating, plank grating, and fiberglass-reinforced plastic (FRP) grating.

Enhancing Structural Integrity with Grating Clamps

Now, let’s dive into how grating clamps contribute to the overall strength and longevity of a structure:

1. Prevention of Movement and Instability

Loose gratings can lead to safety hazards and structural weaknesses. Grating clamps secure the grating tightly, preventing it from shifting under load. This stability enhances the durability of the structure as a whole.

2. Protection Against Corrosion

Grating clamps, especially those made from steel or galvanized materials, resist rust and corrosion. This is particularly beneficial for outdoor or industrial environments where exposure to moisture, chemicals, or harsh weather conditions is common.

3. Flexibility for Expansion and Maintenance

One of the standout features of grating clamps is their ability to be reused. This flexibility allows structures to adapt to changing requirements without compromising safety or structural integrity.

4. Weight Distribution and Load-bearing

Grating clamps ensure proper weight distribution across the grating surface, reducing the risk of localized stress or deformation. This is essential for heavy-duty applications like industrial walkways or bridge decking.

5. Cost-Effective Solution

While seemingly small, grating clamps can significantly reduce installation and maintenance costs. Their durability and reusability make them a cost-efficient choice for long-term structural solutions.

Key Benefits of Using Grating Clamps

Why should you consider grating clamps for your next project? Here are some compelling reasons:

- Ease of Installation: No welding or drilling is required.

- Versatility: Compatible with various grating types and sizes.

- Safety: Reduces risks associated with loose or unstable gratings.

- Durability: Made from corrosion-resistant materials for an extended lifespan.

- Environmentally Friendly: Minimal impact on the base structure reduces waste and material usage.

Types of Grating Clamps

There’s no one-size-fits-all when it comes to grating clamps. The type you need depends on your specific application. Here are some common types:

- Saddle Clamps

Ideal for securing bar gratings, saddle clamps are simple to install and provide excellent stability.

- C-Clamps

C-shaped clamps are often used for temporary installations or where frequent removal is needed.

- G-Clamps

These clamps offer a robust grip and are perfect for high-load environments.

- Custom Clamps

For unique applications, custom-designed clamps can be manufactured to meet specific requirements.

Applications of Grating Clamps

Grating clamps are indispensable across various industries. Some typical applications include:

- Industrial Walkways: Ensuring safety and stability in factories and power plants, grating clamps keep walkways secure, even under heavy machinery and foot traffic.

- Bridges and Platforms: Securing grating on load-bearing structures, prevents movement and enhances the longevity of these vital pathways.

- Oil and Gas Facilities: Withstanding harsh marine and chemical conditions, these clamps provide reliable support in highly corrosive environments.

- Architectural Projects: Adding a sleek, modern touch to design-oriented structures, grating clamps merge function with an appeal.

- Water Treatment Plants: Grating clamps ensure durable platforms and walkways in environments exposed to moisture and corrosive agents.

- Shipping Ports and Docks: These clamps hold up gratings on docks and platforms, offering stability for heavy vehicles and machinery.

- Mining Operations: In rugged conditions, grating clamps ensure secure installations for safe movement around mining sites.

Tips for Choosing the Right Grating Clamps

Selecting the right grating clamps is crucial for achieving optimal performance. Keep these tips in mind:

- Material: Choose corrosion-resistant materials for outdoor or industrial applications.

- Load Requirements: Consider the weight and traffic the grating will endure.

- Grating Type: Ensure compatibility with the specific grating design and dimensions.

- Ease of Installation: Opt for clamps that simplify the installation process.

- Compliance: Verify that the clamps meet industry standards and safety regulations.

Final Thoughts

Grating clamps may seem like small, inconspicuous components, but their impact on structural integrity is undeniable. By securing gratings effectively, these clamps contribute to the safety, durability, and adaptability of a wide range of structures.

Whether you are working on an industrial project, a bridge, or an architectural masterpiece, choosing the right grating clamps is key to ensuring long-lasting performance. So, don’t overlook this vital component—invest in quality grating clamps for a stronger, safer structure.

At Greatweld Engineering, we provide high-quality grating clamps designed for long-lasting performance and uncompromised safety. Don’t settle for less—invest in the best. Visit us at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India. For more details, visit our website www.greatweld.com or call us at 8956049361. Strong, safe, and reliable—choose Greatweld Engineering today.