Excerpt:

Choosing the right steel grating for your project can be a tough decision. This guide will walk you through the key considerations, specifications, and options to help make the right choice.

Introduction

When it comes to industrial projects, choosing the right steel grating is essential. Whether you are working on construction, walkways, platforms, or even drainage covers, selecting the right type of grating can make all the difference. From load-bearing capacity to corrosion resistance, there are multiple factors to consider.

In this guide, we’ll break down everything you need to know about selecting the perfect steel grating for your project, covering key considerations such as material, type, specifications, and application.

Why Steel Grating is Essential for Industrial Projects

Steel grating is widely utilized in industrial settings because of its long-lasting durability, robust strength, and ability to resist corrosion. However not all steel grating is created equal, and the wrong choice could lead to inefficiencies, added costs, or even safety hazards.

So, what makes steel grating so essential? Simply put, it provides a robust, slip-resistant surface that can bear heavy loads. Plus, steel is highly customizable, making it suitable for a wide range of environments.

Now, let’s dive into how to choose the right steel grating for your project by exploring the key factors you should consider.

Key Considerations for Choosing Steel Grating for Your Project

- Material Selection: Stainless Steel vs. Carbon Steel

The first decision you need to make when choosing steel grating for your project is the type of material.

- Stainless Steel: Known for its high resistance to corrosion, stainless steel is a great option for outdoor environments or areas exposed to moisture and chemicals. It’s also low maintenance but tends to be more expensive.

- Carbon Steel: If your project involves an indoor application or doesn’t face extreme weather, carbon steel is a budget-friendly choice. It provides excellent strength but requires regular maintenance to prevent rust.

Your choice of material will largely depend on the environmental conditions of your project and your budget.

- Load Capacity and Strength Requirements

Before selecting a steel grating, you’ll need to know the load capacity required for your project. Different gratings are designed to handle different levels of weight, and overloading can cause serious safety issues.

Here are the types of loads to consider:

- Pedestrian Load: If the steel grating will be used in areas with foot traffic, like walkways or pedestrian bridges, the grating should have a slip-resistant surface and be able to support the human weight without deforming.

- Heavy Load: If vehicles or heavy machinery will be traversing the steel grating, it’s crucial to choose a high-strength grating that can handle the extra load without compromising safety.

Most manufacturers provide steel grating specifications, so be sure to match the load requirements to the grating’s rated capacity.

- Grating Types: Press-Locked vs. Welded Gratings

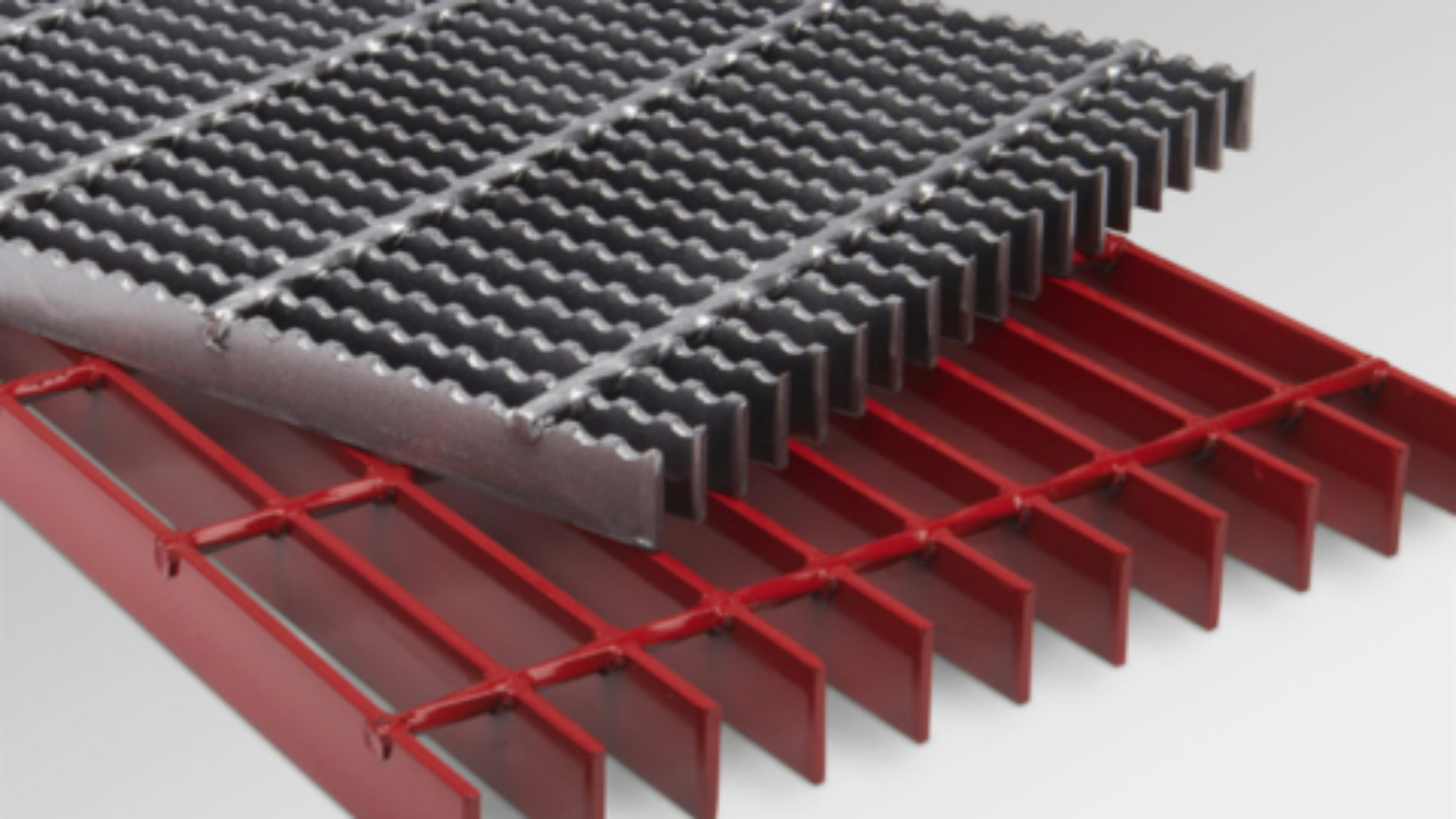

Not all steel gratings are constructed the same way, and the type of manufacturing process plays a significant role in their strength and durability. The two main types are:

- Press-Locked Gratings: These gratings are mechanically locked together, making them ideal for lighter applications. They are usually less expensive but may not have the same load-bearing capacity as welded gratings.

- Welded Gratings: As the name implies, welded gratings are made by welding cross bars and bearing bars together. These are stronger and more durable, making them suitable for heavy-duty applications like industrial platforms and roadways.

- Surface Finish and Coatings:Surface finish plays an important role in how well the steel grating will resist corrosion and wear. There are three common types of finishes:

- Galvanized: Hot-dip galvanized steel offers excellent resistance to corrosion and is ideal for outdoor environments. The coating also protects against rust, ensuring a long lifespan.

- Painted: Painted steel is more suited for indoor applications and provides some protection against corrosion, but it’s not as durable as galvanized steel.

- Plain Steel: If your project doesn’t require additional protection from moisture or chemicals, you can opt for plain steel. However, keep in mind it will need regular maintenance to prevent rust.

- Size and Configuration:Steel gratings come in various sizes and configurations, depending on their application. When choosing the size, consider:

- Bar spacing: Closer spacing offers better support and safety, while wider spacing allows for better drainage.

- Panel size: Large panels are suitable for heavy-duty areas like parking lots, while smaller panels are better for pedestrian use.

Keep in mind that you can usually customize the configuration of the grating to suit your project’s specific needs.

Steel Grating Specifications to Keep in Mind

When selecting steel grating for your project in India, or anywhere else, it’s crucial to follow the necessary specifications. Most grating manufacturers provide standardized specs to make the selection process easier, but here are some key factors:

- Bearing Bar Size: This defines the load-bearing capacity of the grating. The size usually ranges from 25mm to 50mm.

- Cross Bar Spacing: The cross bars play a crucial role in evenly distributing the load across the grating. Spacing can vary from 30mm to 100mm, depending on the project’s requirements.

- Grating Height: The height of the grating can also affect its load capacity and weight. Taller gratings tend to offer more strength but can also be heavier and harder to install.

Common Applications of Steel Grating

Now that you understand the key considerations for choosing the right steel grating, let’s look at some common applications:

- Walkways and Platforms: Steel grating is often used in industrial walkways, catwalks, and platforms due to its durability and slip-resistant surface.

- Drainage Covers: For water drainage systems, steel gratings allow for proper water flow while providing a sturdy surface.

- Parking Lots: Heavy-duty steel gratings can be used in parking areas to support the weight of vehicles while allowing for drainage.

Conclusion

Choosing the right steel grating for your project isn’t just about selecting the strongest or most expensive option. By considering factors like material, load capacity, grating type, and environmental conditions, you can ensure that your choice is both cost-effective and durable for years to come.

Make the right choice for your steel grating needs with Greatweld Engineering. Visit our website greatweld.com, call us at 8956049361, or stop by our location at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India. Our expert team offers cost-effective and durable steel grating solutions tailored to your project. Don’t compromise on quality—contact Greatweld Engineering today .