Introduction:

Looking for the perfect flooring solution? Dive into our comprehensive comparison of steel grating vs. other flooring solutions to understand why steel grating takes the lead in strength, safety, and cost-effectiveness.

Flooring might not be the first thing on your mind when designing industrial or commercial spaces, but it plays a critical role in ensuring safety, durability, and efficiency. When it comes to heavy-duty flooring solutions, steel grating often emerges as the top choice. Why? Because it checks all the boxes for strength, safety, cost-effectiveness, and low maintenance.

But how does it compare to other flooring options like solid flooring, concrete, or plastic panels? Let’s break it all down and see why steel grating is the go-to option for industries worldwide.

What is Steel Grating?

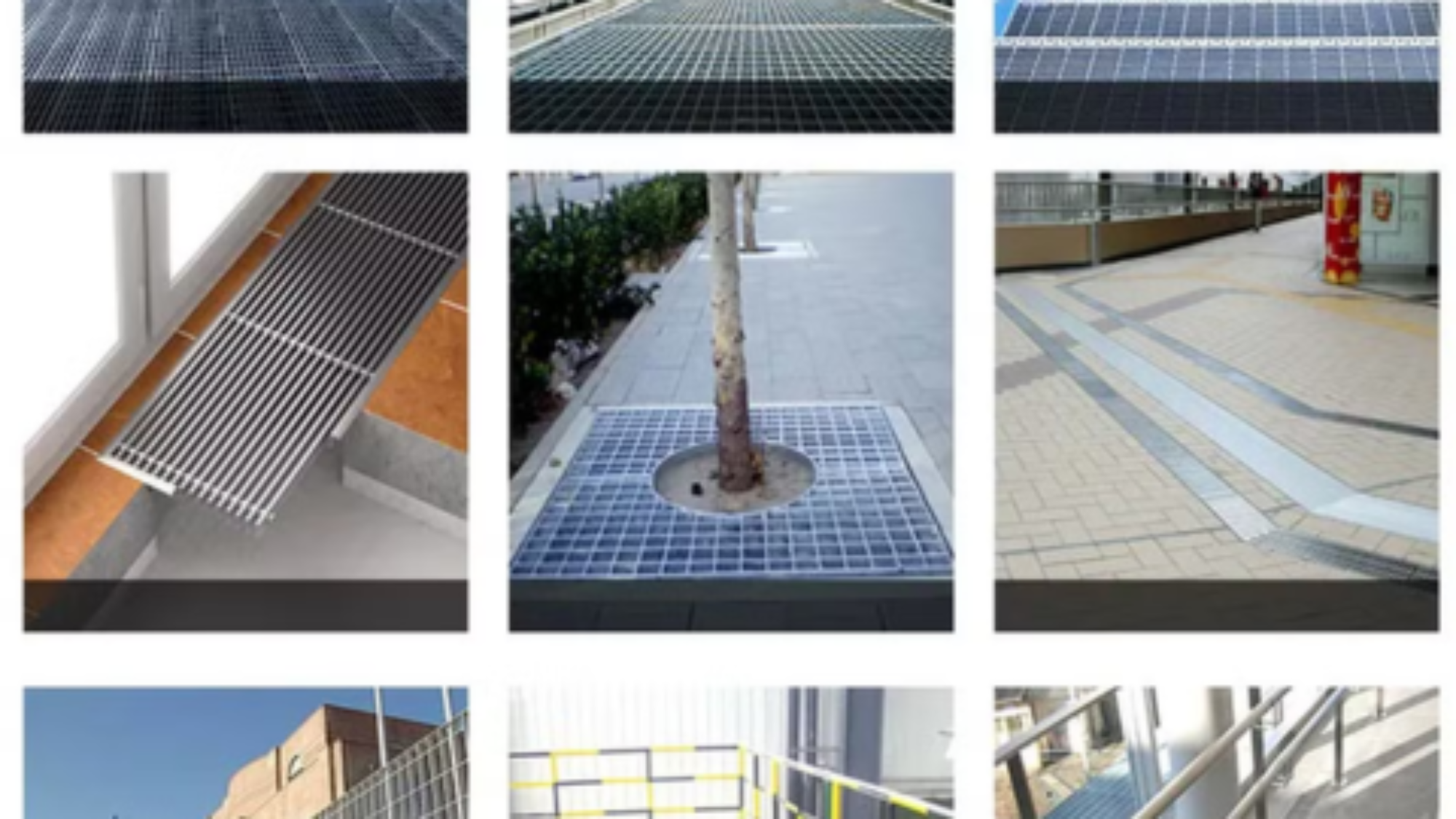

Before diving into comparisons, let’s get clear on what steel grating is. Steel grating is a grid-like flooring solution made from interconnected metal bars. It’s known for its strength, versatility, and open-grid design, which makes it ideal for industrial and commercial use. Whether it’s for factory floors, walkways, or drainage covers, steel grating offers unmatched functionality.

Comparing Steel Grating to Other Flooring Solutions

Now, let’s pit steel grating against popular flooring options to see where it truly excels.

- Steel Grating vs. Solid Flooring

Solid flooring, such as concrete slabs or metal plates, is a common choice for heavy-duty applications. However, when compared to steel grating, it falls short in several areas.

Advantages of Steel Grating Over Solid Flooring:

- Better Drainage and Ventilation: Steel grating’s open-grid design allows liquids, debris, and air to pass through easily. Solid flooring, on the other hand, can trap water and debris, leading to maintenance challenges.

- Lighter Weight: Despite its strength, steel grating is much lighter than solid metal or concrete flooring, reducing the overall structural load.

- Improved Safety: Steel grating provides excellent slip resistance, even in wet or oily conditions. Solid flooring can become slippery, posing a safety hazard.

- Cost-Efficiency: Steel grating often costs less to install and maintain compared to heavy solid flooring options.

When safety, drainage, and ease of maintenance are priorities, steel grating easily wins over solid flooring.

- Steel Grating vs. Concrete Flooring

Concrete flooring is another popular option, especially in warehouses and factories. But steel grating still outshines it in several critical areas.

Why Steel Grating is Better Than Concrete:

- Durability: While concrete can crack or chip over time, steel grating is highly durable and can withstand extreme weights and impacts without damage.

- Corrosion Resistance: Steel grating made from galvanized or stainless steel is resistant to rust and corrosion, making it suitable for harsh environments. Concrete, when exposed to moisture and chemicals, tends to degrade.

- Installation Time: Installing concrete flooring can be a time-consuming process involving curing and drying. Steel grating, on the other hand, is quick to install.

- Customizability: Steel grating comes in various designs, sizes, and materials, offering greater flexibility than plain concrete floors.

In industries where exposure to chemicals or moisture is common, steel grating proves to be the more reliable option.

- Steel Grating vs. Plastic Flooring Panels

Plastic flooring panels are lightweight and often used in areas with minimal load-bearing requirements. But how do they compare with steel grating?

Steel Grating Outperforms Plastic Flooring in:

- Strength and Load-Bearing Capacity: Steel grating can support heavy equipment, vehicles, and foot traffic. Plastic panels, while cheaper, cannot handle heavy loads.

- Heat Resistance: Steel grating remains unaffected by high temperatures, while plastic can warp or melt under heat.

- Longevity: Steel grating lasts significantly longer than plastic flooring, which is prone to wear and tear over time.

- Eco-Friendliness: Steel is recyclable, making it a sustainable choice compared to plastic, which often ends up in landfills.

For high-performance environments, steel grating is the clear winner over plastic flooring.

- Steel Grating vs. Wood Flooring

Wood flooring may be aesthetically pleasing, but it’s not designed for heavy-duty or industrial applications.

Steel Grating’s Advantages Over Wood Flooring:

- Fire Resistance: Steel grating is non-combustible, while wood is highly flammable.

- Low Maintenance: Unlike wood, which requires frequent polishing and protection against termites, steel grating is virtually maintenance-free.

- Longer Lifespan: Steel grating is built to last, whereas wood can rot, warp, or break under pressure.

For industrial and commercial settings, steel grating far outperforms wood in terms of durability and functionality.

Why Steel Grating Stands Out: The Key Benefits

By now, it’s clear that steel grating outshines other flooring options in multiple ways. Let’s recap its standout benefits:

- Strength and Durability

Steel grating can handle heavy loads and constant use without bending or breaking. It’s perfect for industries like manufacturing, oil and gas, and transportation.

- Superior Safety Features

The anti-slip surface of steel grating reduces the risk of accidents, making it an ideal choice for areas prone to spills or wet conditions.

- Low Maintenance

With its open-grid design, steel grating doesn’t trap debris or water, cutting down on cleaning and maintenance costs.

- Versatility

Available in a variety of materials (stainless steel, galvanized steel, aluminum), steel grating can be customized to meet specific requirements.

- Cost-Effectiveness

While steel grating offers premium performance, it remains cost-effective in the long run due to its durability and low upkeep needs.

Ideal Applications for Steel Grating

Steel grating is the preferred flooring solution for:

- Factories and Warehouses: For handling heavy machinery and equipment.

- Oil Rigs and Chemical Plants: Due to its resistance to corrosion and chemicals.

- Walkways and Platforms: For superior safety and ventilation.

- Parking Lots and Drainage Covers: Thanks to its load-bearing capacity and drainage features.

FAQs About Steel Grating

Q1. Is steel grating suitable for outdoor use?

Yes! Steel grating is highly resistant to weathering and corrosion, making it perfect for outdoor applications.

Q2. How does steel grating ensure safety?

Its anti-slip surface and open-grid design provide better traction and prevent water or debris buildup.

Q3. Is steel grating cost-effective?

Absolutely. While the upfront cost may vary, its durability and low maintenance make it a long-term cost-effective solution.

Q4. Can steel grating be customized?

Yes, steel grating comes in various materials, sizes, and patterns to suit different needs.

Wrapping Things Up

When comparing steel grating vs. other flooring solutions, it’s clear that steel grating offers unmatched benefits in terms of strength, safety, and cost-efficiency. Its durability and low-maintenance appeal make it a reliable choice for industrial and commercial applications.

Whether you are building a factory floor, walkway, or platform, steel grating is the smart choice for a long-lasting and efficient flooring solution. So, if you are in the market for flooring that truly stands the test of time, look no further than steel grating.

Choose Greatweld Engineering for premium-quality steel grating solutions tailored to your needs. Located at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India, we are your trusted partner in strength and efficiency. For more details, call us at 8956049361 or visit our website at https://greatweld.com/. Contact us today.