Excerpt:

The steel grating industry is evolving rapidly with new technologies and trends shaping the future. From enhanced materials to sustainability-focused innovations, find out how these changes will impact the market.

As industries evolve, the steel grating sector is no exception. From construction to manufacturing, steel grating plays a crucial role in various applications. But with new demands, evolving technologies, and a global shift toward sustainability, the future of steel grating is looking more dynamic than ever. This blog dives into emerging technologies, key innovations, and future trends in the steel grating industry, with a special emphasis on how these trends are shaping markets like India.

- What Is Steel Grating?

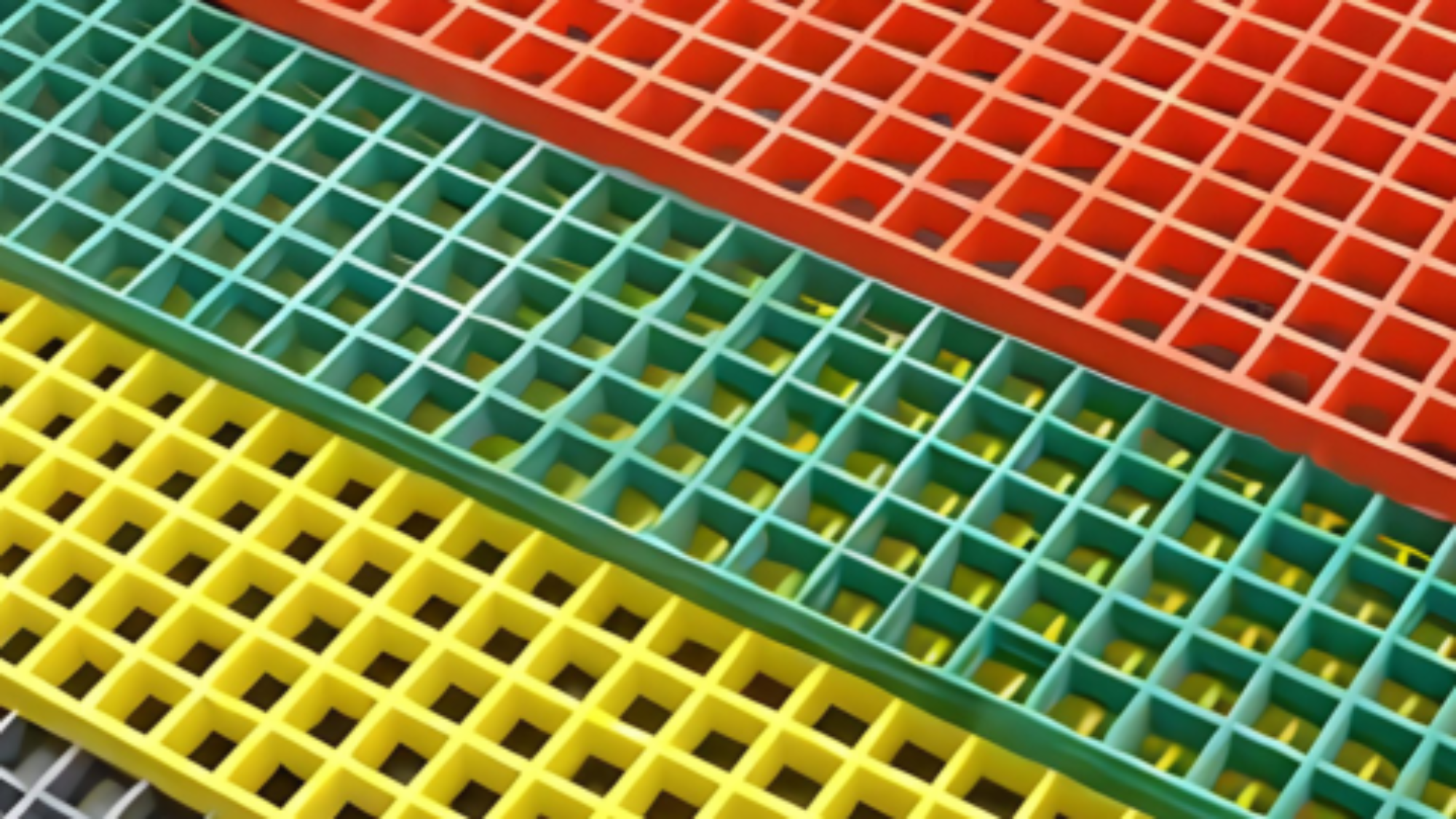

Steel grating refers to a framework made of steel bars, typically used for creating platforms, walkways, stair treads, and drainage covers. Thanks to its high strength, durability, and load-bearing capacity, steel grating has become indispensable across industries like construction, oil and gas, automotive, and more. But as these industries grow and new challenges arise, the demand for innovative steel grating solutions is increasing.

- Key Emerging Technologies Shaping the Future of Steel Grating

- Advanced Materials for Durability and Sustainability

One of the most exciting shifts in the future of steel grating lies in the adoption of advanced materials. Traditionally, carbon steel or stainless steel has been the go-to materials for grating. However, industries are moving toward composite grating or the use of high-performance alloys that offer increased corrosion resistance, durability, and reduced weight. These advancements make the steel grating more versatile and suitable for extreme environments, such as offshore oil platforms or chemical plants.

In addition, the push for sustainability is driving the use of recycled materials in steel grating production. This not only reduces the environmental footprint but also aligns with global sustainability goals, a critical consideration for future industrial projects.

- Automated Manufacturing and Smart Technology Integration

Automation is transforming industries globally, and the steel grating sector is no different. The integration of smart technologies like robotics, AI-driven manufacturing, and 3D printing is streamlining production processes, increasing precision, and minimizing waste.

For instance, CNC (Computer Numerical Control) technology allows for the precise cutting and assembly of steel grating, ensuring consistent quality and reducing manual errors. Meanwhile, smart sensors can monitor the wear and tear of grating structures in real-time, providing alerts for maintenance and preventing accidents before they happen. Such innovations are critical for industries where safety and reliability are paramount.

- Customization and Modular Grating Systems

Customization is a growing trend across industries, and steel grating is no exception. Future designs are expected to focus on modular systems, allowing for faster installation and more adaptable applications. These systems enable users to easily customize grating for specific project requirements without having to start from scratch.

For example, in sectors like oil and gas or infrastructure development, having modular grating solutions means faster project timelines and reduced labour costs. This is especially relevant in regions like India, where rapid urbanization and industrialization are driving the need for scalable, cost-effective solutions.

- The Future of Steel Grating in India

India is poised to become one of the major players in the steel grating industry due to its booming infrastructure development and expanding industrial base. The future of steel grating in India is shaped by several factors, including government policies promoting infrastructure, the growing construction sector, and increasing foreign investments in industrial projects.

A) Rapid Infrastructure Growth

With urbanization in full swing, India’s infrastructure needs are skyrocketing. From building new airports to expanding metro systems and constructing massive smart cities, the demand for steel grating in public infrastructure projects is set to grow exponentially. Steel grating is ideal for these applications due to its cost-efficiency, strength, and adaptability.

- Sustainability and Environmental Regulations

As the global focus shifts toward sustainability, India is following suit. The country’s regulatory framework is increasingly favouring green building materials and energy-efficient construction practices. The steel grating future trend in India will likely lean towards the adoption of recycled steel and eco-friendly production methods. This trend aligns with both global sustainability efforts and India’s goal of reducing its carbon footprint.

- Innovation and Technological Adoption

Although traditionally seen as a low-tech industry, Indian steel manufacturers are beginning to embrace automation and digital technologies in production. With global competition intensifying, local players are investing in state-of-the-art equipment to boost efficiency, cut costs, and improve quality. The use of AI and machine learning in predictive maintenance and quality control is expected to grow in the coming years, positioning India as a leader in advanced steel grating solutions.

- Global Steel Grating Future Trends

Beyond India, the global steel grating industry is also experiencing a transformation. Some key trends include:

- Sustainability: The industry is witnessing an increased use of green manufacturing processes, including energy-efficient production techniques and the use of renewable energy.

- Corrosion Resistance: New coatings and treatments are emerging, offering greater protection against corrosion, especially in harsh environments such as offshore or chemical industries. Galvanized steel grating remains popular due to its long-lasting durability.

- Lightweight Solutions: As industries like automotive and aerospace push for lighter materials, there is growing interest in lightweight steel grating that maintains strength but reduces weight, aiding in fuel efficiency and reducing transportation costs.

- Challenges and Opportunities for the Future

While the future of steel grating looks promising, there are challenges to consider. For one, the volatile steel prices caused by fluctuating raw material costs and tariffs could impact the affordability of steel grating solutions. In addition, as industries adopt newer technologies, the skills gap in the labour market might slow down the pace of innovation.

On the other hand, these challenges open up new opportunities for companies willing to invest in research and development (R&D) and workforce training. Firms that focus on creating innovative, sustainable, and cost-effective solutions will thrive in the coming years.

- Conclusion: The Road Ahead

The future of steel grating blends technology, sustainability, and innovation. With advanced materials, smart manufacturing, and rising demand for modular solutions, the industry is set for major transformation. In India, rapid infrastructure growth and a focus on sustainability could make the country a key global player. As industries evolve, steel grating must become smarter, more efficient, and eco-friendly—not just stronger and more durable.

Greatweld Engineering is ready to meet these evolving demands. Visit our website greatweld.com, call us at 8956049361, or visit us at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India to learn more.