Excerpt:

Gratings are versatile materials used in multiple industries, offering solutions for structural support, safety, and ventilation. Learn about the different types of gratings and their applications in various sectors.

Introduction

Gratings are an essential component in a wide range of industrial applications. They provide structural support, enhance safety, and allow for ventilation and drainage. From construction sites to manufacturing plants, gratings are often overlooked yet indispensable tools that come in various designs and materials.

What Are Gratings?

Gratings are frameworks made from parallel or crossed bars, creating open spaces for air, light, liquids, or debris to pass through. Typically made from materials like steel, aluminum, or fiberglass, gratings are valued for their strength and durability. They are commonly used for flooring, walkways, platforms, and drainage covers, serving to provide support, enhance safety, and ensure proper ventilation.

Types of Gratings and Their Applications

Gratings come in various types, each designed to fulfil specific roles based on material, load-bearing capacity, and environmental factors. Let’s explore the different types of gratings and how they are applied across industries.

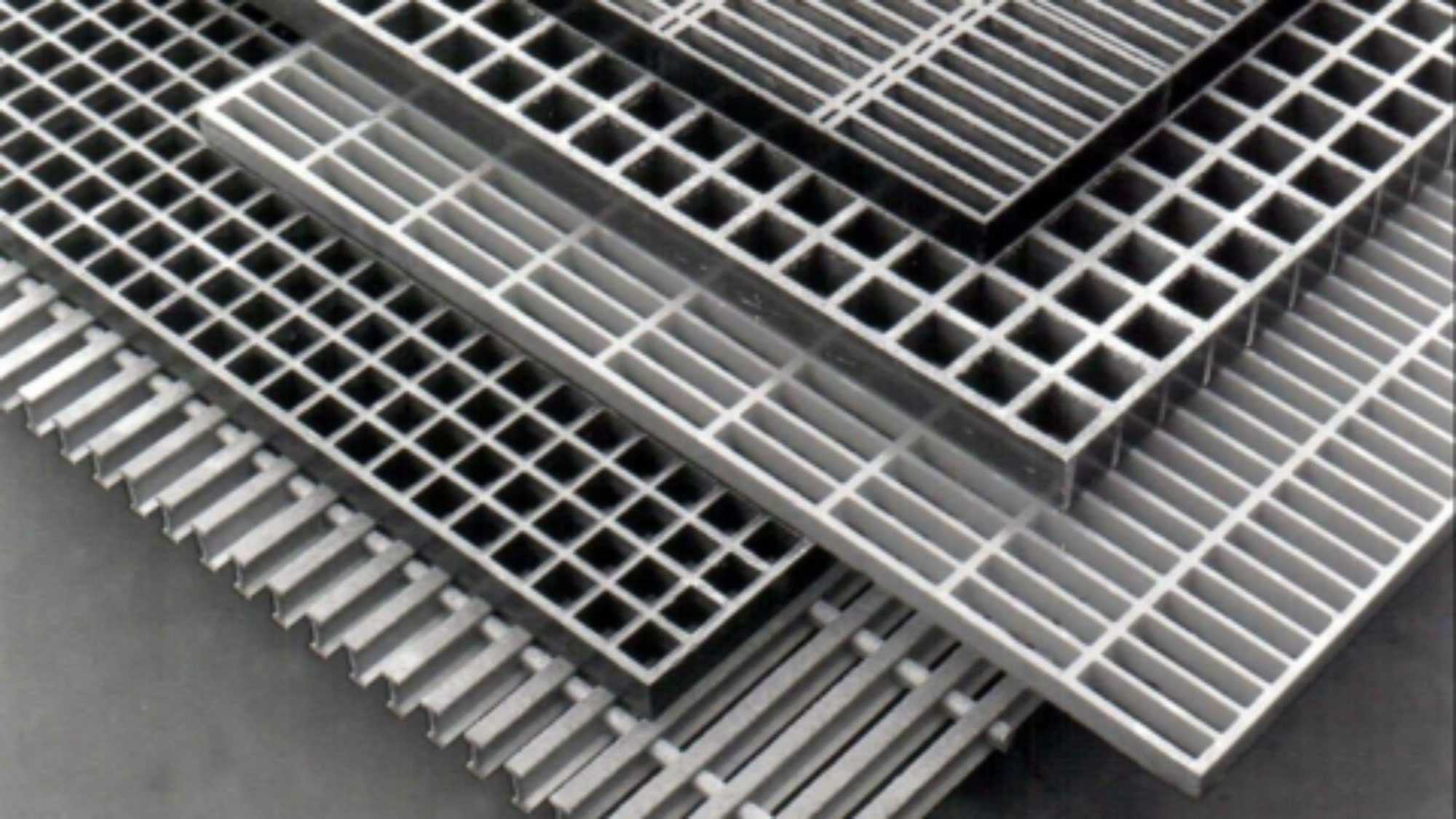

- Bar Grating

Description:

Bar grating is one of the most common and versatile grating types. It is made from bearing bars that are spaced evenly and cross bars that hold them together, forming a grid-like pattern. This type of grating can be made from materials such as steel, aluminium, and stainless steel.

Applications:

Bar grating is widely used in industrial and commercial settings. Its primary use is for flooring, platforms, stair treads, and walkways due to its strength and ability to handle heavy loads. This grating type is commonly found in oil refineries, power plants, chemical factories, and shipyards.

Key Benefits:

- High load-bearing capacity

- Durable and resistant to wear and tear

- Available in a variety of materials, making it suitable for different environments

- Expanded Metal Grating

Description:

Expanded metal grating is created by cutting and stretching a sheet of metal, which results in a diamond-shaped pattern. This type of grating is lightweight but still strong enough for many industrial uses. It provides excellent ventilation while maintaining a non-slip surface.

Applications:

Expanded metal grating is ideal for walkways, platforms, and ventilation grilles in industries where a lightweight yet durable solution is required. It is often used in areas such as HVAC systems, machine guarding, and security fencing.

Key Benefits:

- Lightweight yet strong

- Allows for excellent airflow and drainage

- Cost-effective solution for non-slip surfaces

- Fiberglass Grating (FRP Grating)

Description:

Fiberglass Reinforced Plastic (FRP) grating is made from a composite material of fiberglass and resin. It offers corrosion resistance and is non-conductive, making it an excellent choice for applications where electrical hazards or exposure to corrosive substances are a concern.

Applications:

FRP grating is often used in industries like chemical processing, wastewater treatment, and marine environments where exposure to chemicals or saltwater could cause metal gratings to corrode. It is also used in industries where safety is paramount, such as in areas with a high risk of electrical hazards.

Key Benefits:

- Corrosion-resistant

- Non-conductive and lightweight

- Low maintenance and durable in harsh environments

- Press-Locked Grating

Description:

Press-locked grating is made by permanently locking cross bars into bearing bars through a combination of pressure and heat, resulting in a smooth and aesthetically pleasing finish. This type of grating is often used in areas where appearance is as important as functionality.

Applications:

Press-locked grating is frequently used in architectural applications, such as building facades, fencing, and decorative installations. It is also used in flooring and walkways that require a sleek and modern appearance.

Key Benefits:

- Smooth surface for aesthetic appeal

- Strong and durable

- Available in various sizes and materials

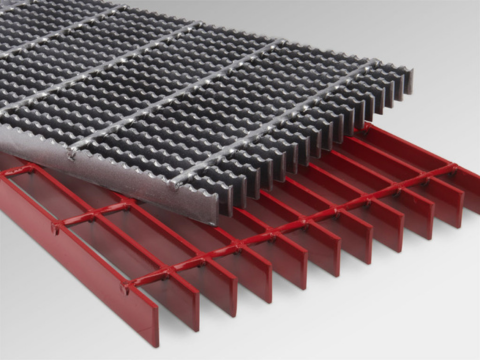

- Welded Steel Grating

Description:

Welded steel grating is constructed by welding cross bars to bearing bars, forming a sturdy and durable structure. The welded joints provide additional strength, making this grating suitable for heavy-duty applications. It is often made from carbon steel and is available in galvanized or plain finishes.

Applications:

Welded steel grating is commonly used in industries requiring heavy load-bearing capabilities, such as mining, manufacturing, and transportation. It is ideal for trenches, industrial flooring, and ramps where strength and durability are essential.

Key Benefits:

- Extremely strong and durable

- Suitable for heavy-duty applications

- Can be galvanized for corrosion resistance

- Swage-Locked Grating

Description:

Swage-locked grating is similar to press-locked grating, but instead of pressure, swaging is used to lock the cross bars and bearing bars together. This creates a tight, secure bond that increases the grating’s overall strength while maintaining a clean appearance.

Applications:

Swage-locked grating is often used in environments requiring high strength and durability, such as industrial plants and offshore platforms. It is also used for pedestrian bridges and walkways, offering a combination of safety, strength, and aesthetics.

Key Benefits:

- High strength and durability

- Clean, smooth finish

- Suitable for both industrial and architectural applications

Choosing the Right Grating for Your Application

When selecting the right grating for your specific application, several factors come into play, including:

- Material:

Depending on the environment, you may need a material that offers corrosion resistance (FRP or stainless steel) or one that provides extra strength (welded steel). - Load Capacity:

Consider the weight-bearing requirements of your application. Bar and welded steel gratings are ideal for heavy-duty uses, while expanded metal and FRP gratings work well in lighter applications. - Environmental Factors:

In harsh environments where exposure to chemicals, moisture, or electrical hazards is common, materials like FRP or galvanized steel may be more suitable. - Aesthetic Requirements:

For architectural applications where appearance is important, press-locked or swage-locked gratings offer a sleek, modern look without compromising on functionality.

Conclusion

Gratings are vital across industries, offering solutions for flooring, ventilation, and safety. The right choice depends on your specific needs, such as strength, durability, corrosion resistance, or aesthetics. Options like bar grating, expanded metal, FRP, and welded steel each bring unique benefits. Understanding the differences in grating types allows you to make informed decisions that ensure safety and efficiency, delivering long-lasting value in any industry.

For expert guidance and high-quality gratings, reach out to Greatweld Engineering. Our team offers top-notch solutions tailored to your specific needs. Whether you are looking for strength, durability, or corrosion resistance, we provide the right grating options to meet your industrial requirements. Visit our website at https://greatweld.com or contact us at 8956049361. You can also find us at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India. Let Greatweld Engineering help you find the perfect grating solution today.