Introduction:

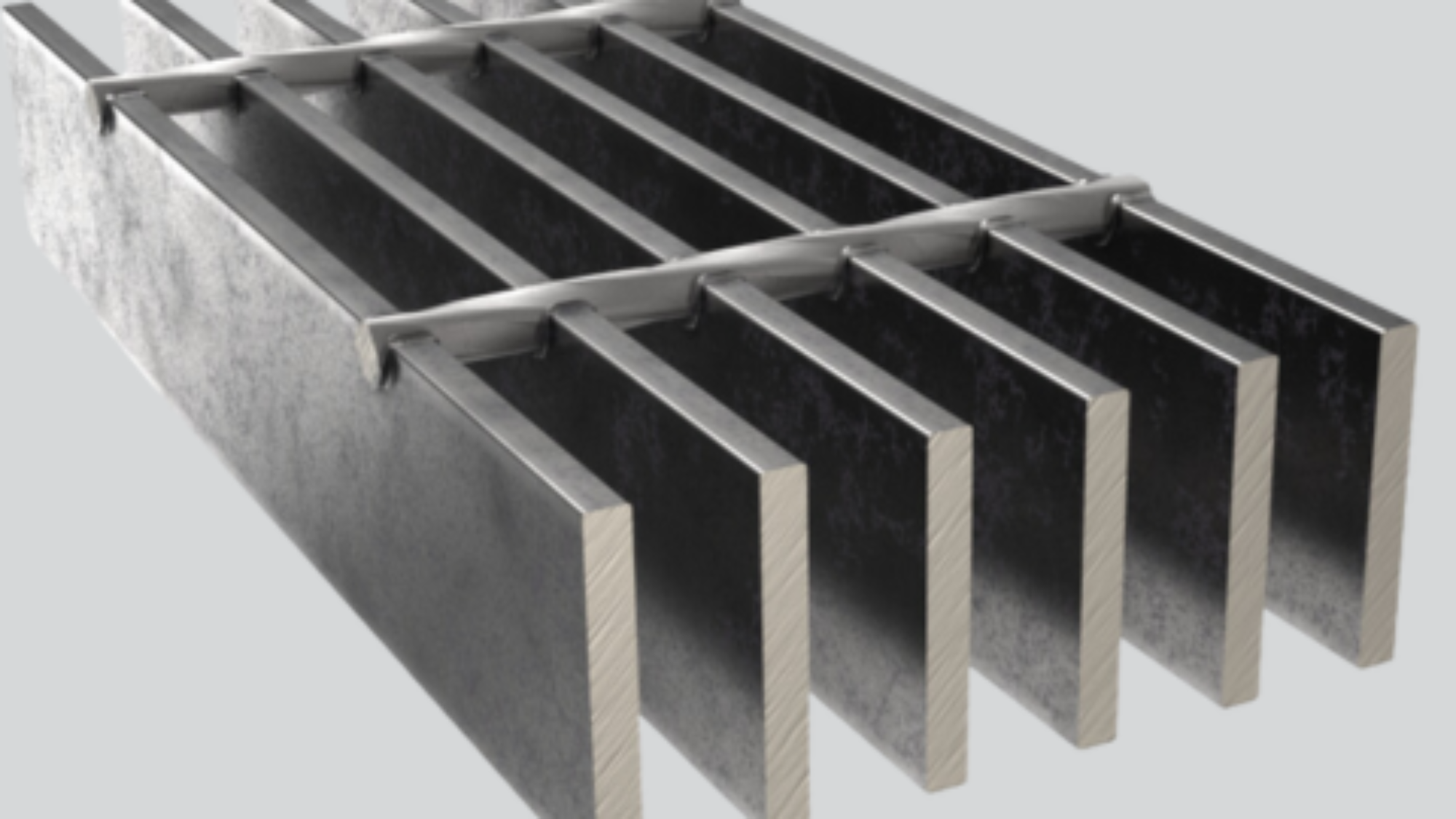

Steel grating has become a staple in various industries, thanks to its strength, flexibility, and cost-effectiveness. In this blog, we’ll dive into the different benefits of choosing steel grating for your next project, whether it’s industrial, commercial, or even residential.

Steel grating is a popular choice in numerous industries for good reason. Its combination of durability, versatility, and cost-effectiveness makes it a go-to material for various projects, from industrial flooring to walkways and stair treads. But what exactly makes steel grating so special? In this article, we’ll explore the various benefits of steel grating and why it could be the perfect fit for your next project.

- Durability and Strength

When it comes to industrial applications, the durability of materials is paramount. Steel grating shines in this department. Thanks to its high strength-to-weight ratio, steel can support heavy loads without bending or warping, making it ideal for high-traffic areas.

- High Load-Bearing Capacity: Steel grating can handle heavy foot traffic, machinery, and even vehicular loads, depending on the thickness and design.

- Longevity: Steel grating is highly resistant to wear and tear, ensuring it lasts for decades with minimal maintenance.

This level of durability means you won’t need to worry about constant replacements or repairs, saving time and money in the long run.

- Versatility in Design and Use

One of the most attractive benefits of steel grating is its versatility. It can be used in a wide range of applications, including industrial floors, pedestrian walkways, platforms, and even decorative installations. The variety of sizes, shapes, and designs available means it can be tailored to suit nearly any project.

- Customizable Options: Steel grating comes in various patterns, including welded, press-locked, and swaged, making it adaptable for multiple uses.

- Different Materials: While carbon steel is the most common choice, stainless steel and aluminium options are also available, providing solutions for different environmental conditions and requirements.

Its flexibility makes steel grating a preferred choice for architects and engineers who need to meet specific safety and aesthetic needs.

- Safety Features

Safety is a major concern in both industrial and commercial settings, and steel grating checks all the right boxes here. The open-grid design of steel grating ensures excellent slip resistance, even in wet or oily conditions. Additionally, its non-slip surface is often improved with serrated edges for added traction.

- Slip Resistance: The open grid allows for better traction, reducing the risk of accidents, especially in environments exposed to moisture or chemicals.

- Enhanced Visibility: The gaps between the steel grates allow for better visibility in low-light conditions, making it easier for workers to navigate spaces safely.

These features make steel grating a reliable option in environments where worker safety is critical, such as factories, oil rigs, and even public walkways.

- Cost-Effectiveness

Steel grating offers an excellent return on investment due to its long lifespan and minimal maintenance needs. While the initial cost may be higher than other materials like wood or plastic, steel’s durability means you won’t need to replace or repair it as frequently.

- Low Maintenance: Steel grating requires very little upkeep beyond occasional cleaning or galvanization to prevent rust.

- Long-Term Savings: Due to its longevity, steel grating saves money over time compared to other materials that may need more frequent replacement or repairs.

Its robustness and resistance to environmental wear make steel grating an economically sound choice for projects where long-term durability is important.

- Ease of Installation

Another benefit of steel grating is how easy it is to install. Thanks to its lightweight structure (relative to its strength), transporting and placing steel grates is a relatively simple process.

- Quick Setup: Steel grating can often be cut to size and fitted without needing specialized equipment or labour.

- Prefabricated Solutions: Many manufacturers offer prefabricated steel grating panels that are ready for immediate installation, reducing labour costs and installation time.

Whether you’re handling a small residential project or a large-scale industrial operation, steel grating can simplify the installation process and help keep timelines on track.

- Environmentally Friendly

Sustainability is a growing concern in modern construction, and steel grating scores well in this area too. Steel is 100% recyclable, meaning that at the end of its lifespan, it can be melted down and reused without losing its quality or strength.

- Recyclability: Steel can be recycled indefinitely, reducing the need for raw materials and lowering the environmental footprint of your project.

- Eco-Friendly Production: Modern steel production methods have become more efficient, using less energy and producing fewer emissions.

Choosing steel grating is not just a smart financial choice but also an environmentally responsible one.

- Corrosion Resistance

In environments exposed to moisture, chemicals, or harsh weather conditions, corrosion can be a major issue. Steel grating, particularly when galvanized or made from stainless steel, offers excellent resistance to corrosion.

- Galvanization: Galvanized steel grating is coated with a protective layer of zinc, which prevents rust and extends the lifespan of the material.

- Stainless Steel Options: For particularly corrosive environments, such as coastal areas or chemical plants, stainless steel grating offers superior resistance to both rust and corrosion.

This corrosion resistance means steel grating can be used outdoors or in harsh environments without succumbing to the elements, making it a great choice for long-term installations.

- Low Maintenance

Once installed, steel grating requires very little attention. It doesn’t need painting, staining, or frequent repairs like other materials. In most cases, a simple cleaning is all that’s needed to keep it in top shape.

- Minimal Upkeep: Aside from periodic inspections and cleaning, steel grating is essentially maintenance-free.

- Resistant to Wear: Its rugged nature means that even in high-traffic areas, steel grating maintains its structural integrity without the need for constant repairs.

The low maintenance aspect makes it an appealing choice for busy industrial environments where downtime for repairs could be costly.

Conclusion

Steel grating offers a wide range of benefits that make it a standout material for industrial, commercial, and even residential applications. From its unmatched durability and corrosion resistance to its ease of installation and low maintenance, steel grating is a versatile solution for numerous projects. Whether you’re concerned about safety, cost-effectiveness, or sustainability, steel grating covers all bases.

Looking for premium steel grating solutions? Contact Greatweld Engineering today and let us provide the perfect solution for your project needs. Visit our website https://greatweld.com/ or contact us at 8956049361 . You can also visit us at Gat No. 213, 214/1, Markal Udyog Nagar, Plot No. C&D, Post Markal, Tal.: Khed, Dist.: Pune – 412105, Maharashtra, India. Let Greatweld Engineering handle all your Steel grating needs with precision and reliability.