Types of Cable Trays

1. Perforated Cable Trays

Our perforated cable trays are ideal for managing cables in environments where ventilation and heat dissipation are essential. These trays help prevent the accumulation of dust and moisture, making them perfect for light and heavy-duty applications as IEC 61537:2023.

Key Features:

- Available in widths from 150mm to 1000mm, heights from 40mm to 150mm, and thicknesses from 1.2mm to 3.0mm.

- Material options include Mild Steel (MS), SS, Aluminium

- Finish options: Pre-galvanized (IS-277), Powder Coated, Painted, Hot Dip Galvanized (IS-2629).

2. Ladder-Type Cable Trays

Designed for heavy-duty cable installations, our ladder-type trays offer high load-bearing capacity. Whether your project requires welded or bolted trays, our solutions ensure adaptability to your environment as per IEC 61537:2023.

Key Features:

- Available in widths from 150mm to 1000mm, heights from 40mm to 150mm, and thicknesses from 1.2mm to 3.0mm.

- Material options: MS, SS, Aluminium.

- Finish options: Pre-galvanized, Powder Coated, Painted, Hot Dip Galvanized (IS-2629), Stainless Steel.

3. Raceways/Trunking Cable Trays

Our raceways and trunking trays are designed for routing power and networking cables in IT companies and industrial environments. With a focus on providing neat and organized cable management, these trays protect cables from physical damage while allowing for quick access during maintenance.

Key Features:

- Widths from 150mm to 1000mm, heights from 30mm to 150mm, and thicknesses from 3mm to 6mm.

- Material options: MS, SS.

- Finish options: GI Hot Dip, Pre-galvanized, Powder Coated, Stainless Steel.

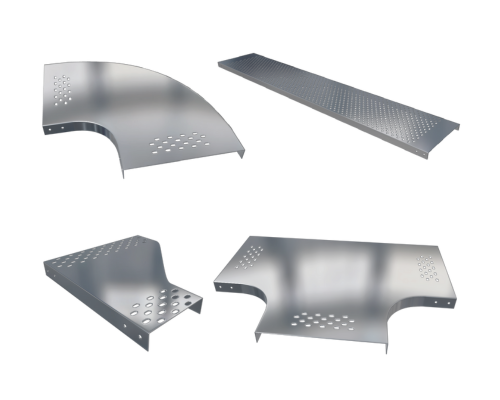

Cable Tray Accessories

Our comprehensive selection of accessories enhances the flexibility and functionality of our cable trays, ensuring smooth installation and adaptability in different environments:

Horizontal & Vertical Bends: For seamless cable routing across different directions.

Crosses & Tees: For multi-directional cable routing at junctions.

Reducers: Transition between different tray sizes.

Coupler Plates: Ensure proper joining and alignment of trays.