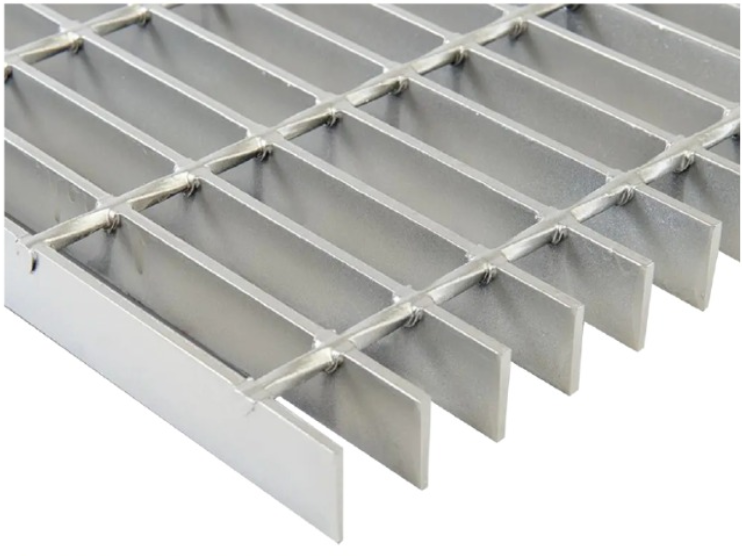

Electroforged Steel Grating

Electroforged Steel Gratings: Durable & High-Performance Solutions for Industrial Applications

Electroforged steel gratings are engineered for superior strength, durability, and safety in heavy-duty industrial applications.

Manufactured using an advanced electroforging process, these gratings fuse steel bars under heat and pressure, creating a seamless, rigid structure stronger than traditional welded gratings. Ideal for factories, oil rigs, and chemical plants, they withstand high-load demands and harsh environments.

Types of Finish

- 1

Self-Coloured

Grating

- 2

Painted/ Red

Oxide Grating

- 3

Galvanized

Grating

Grating Load Chart

The following load chart displays the safe uniform loads for the corresponding bearing bar sizes and spans. These safe uniform loads have been calculated to ensure that the elastic deflection does not exceed 1/200 of the effective span or 10mm, whichever is lesser.

The above values are based on theoretical calculations and a 30% factor of safety is recommended to ensure adequate safety margins.

Serrated Surface

Notched bearing bars provide increased slip resistance. Ideal for applications where moisture or fluids may be present on or near the walking surface

Plain Surface

Standard surface with excellent self-cleaning characteristics. Suitable for most applications.

Key Features of Electroforged Steel Gratings:

Benefits and Applications

Enhanced Durability

Built to withstand heavy loads and high-traffic industrial areas, ensuring long-term performance.

Customizable Surfaces

Available in plain gratings for dry zones and serrated gratings for slip-prone, wet environments—offering anti-slip safety.

Low Maintenance

Minimal upkeep required, lowering operational costs and avoiding frequent replacements.

Versatile Applications

Ideal for industrial walkways, platforms, mezzanines, catwalks, drainage systems, and wastewater treatment plants.

Conclusion

Electroforged steel gratings deliver a reliable, cost-effective, and sustainable solution for industries demanding high performance, safety, and longevity. Their strength, versatility, and low maintenance make them a top choice for industrial infrastructure worldwide.